In order to give you the correct results, we need some data about your machine and cutting fluid you use.

Let's create the model of your first machine that will be used in this calculator. The data you enter will be stored in our system if you want to so that you will have access to this model down the road and use it for one machine - for free. Or just calculate corrections every time you use this calculator.

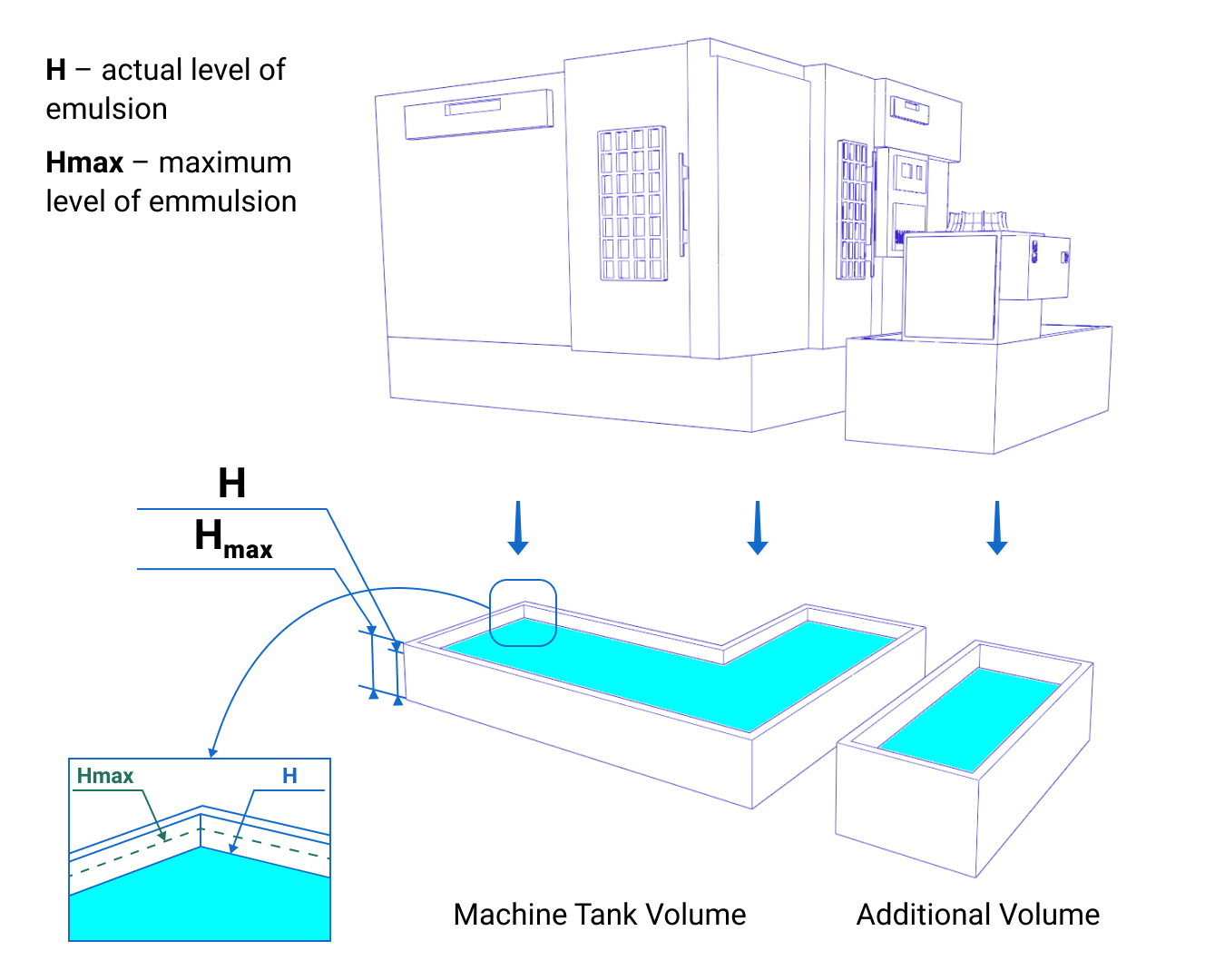

Let’s start with the machine itself. Usually, emulsion in the machine is in the machine tank and some other places like filtration unit and/or high pressure one. We assume, that the emulsion level is changing in the machine tank and it stays the same in the additional volume (filtration unit etc.)

What we need is the geometry of your machine tank and the additional volume if the one exists. Namely, we need to know your machine tank area and the max height of emulsion which we consider as “full”.

Our task is to calculate required corrections to the default mixer so that we end up with target concentration at tank being 100% full, i.e., filled to the max height of emulsion.

Here’s the sketch showing how to calculate one (pretty simple):

Machine sump area, S:

m²Additional volume, AV:

LMax height of emulsion in the machine tank, Hmax:

mAdditional volume, AV:

LMax height of emulsion in the machine tank, Hmax:

mTotal volume, TV:

L