Welcome to EasyFluid!

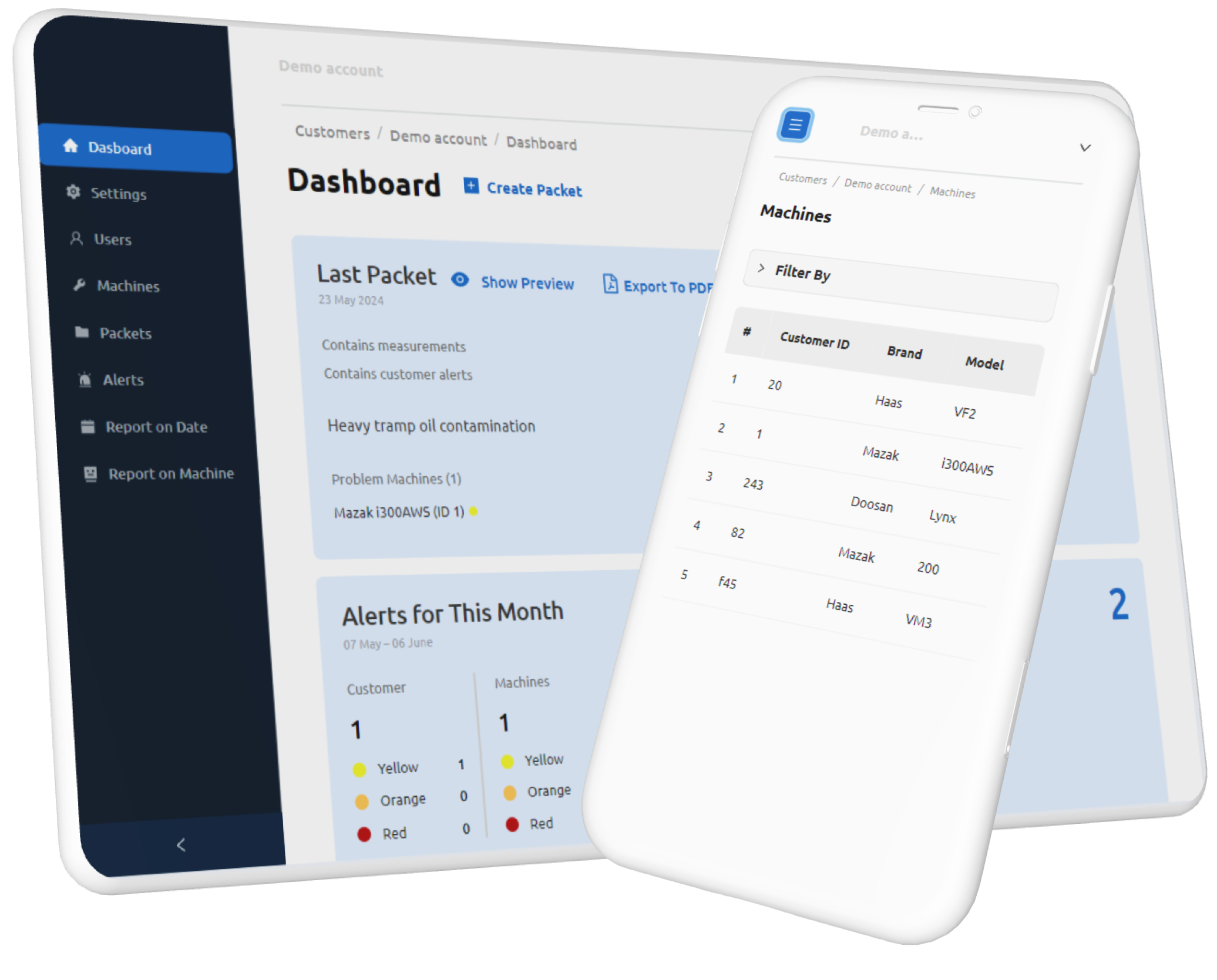

EasyFluid is a web based service for monitoring your metalworking fluids, oils etc.

What’s the point?

The goal of the service is to:

Provide

customers with complete control of what’s going on with your fluids

Reduce spendings

on fluids, make your business more efficient

Reduce risks

related to going outside recommended targets (read - bacterial growth, corrosion, skin allergy etc.)

Features

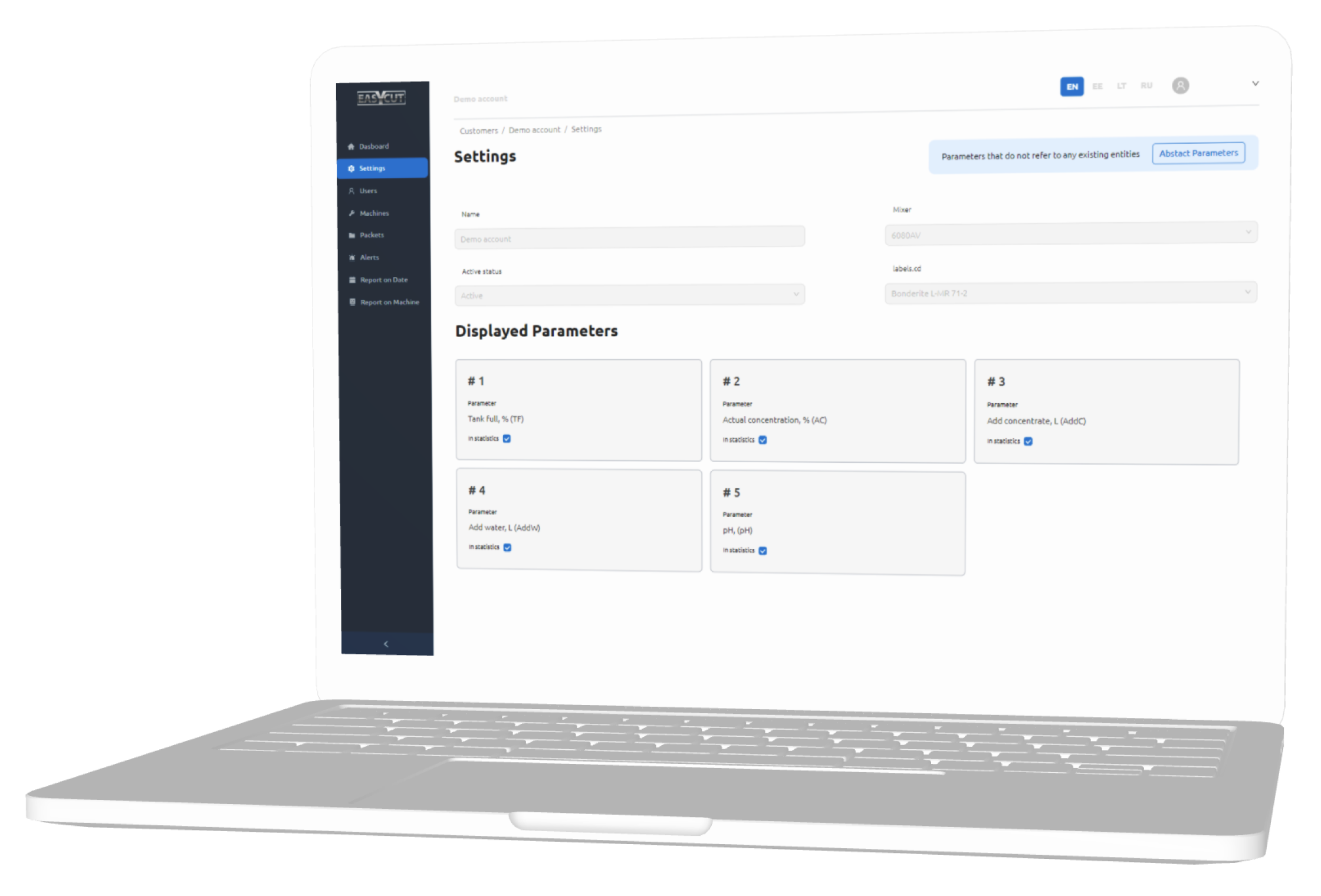

Monitoring

- Keep track of various parameters of your fluids like concentration, pH value, machine sump, level etc.

- Keep track on stock levels of your fluids

- Create your own parameters when needed

- Set up various ranges of different parameters like cutting fluid target concentration and set them as, say, “recommended”, “imperfect” or “not allowed”

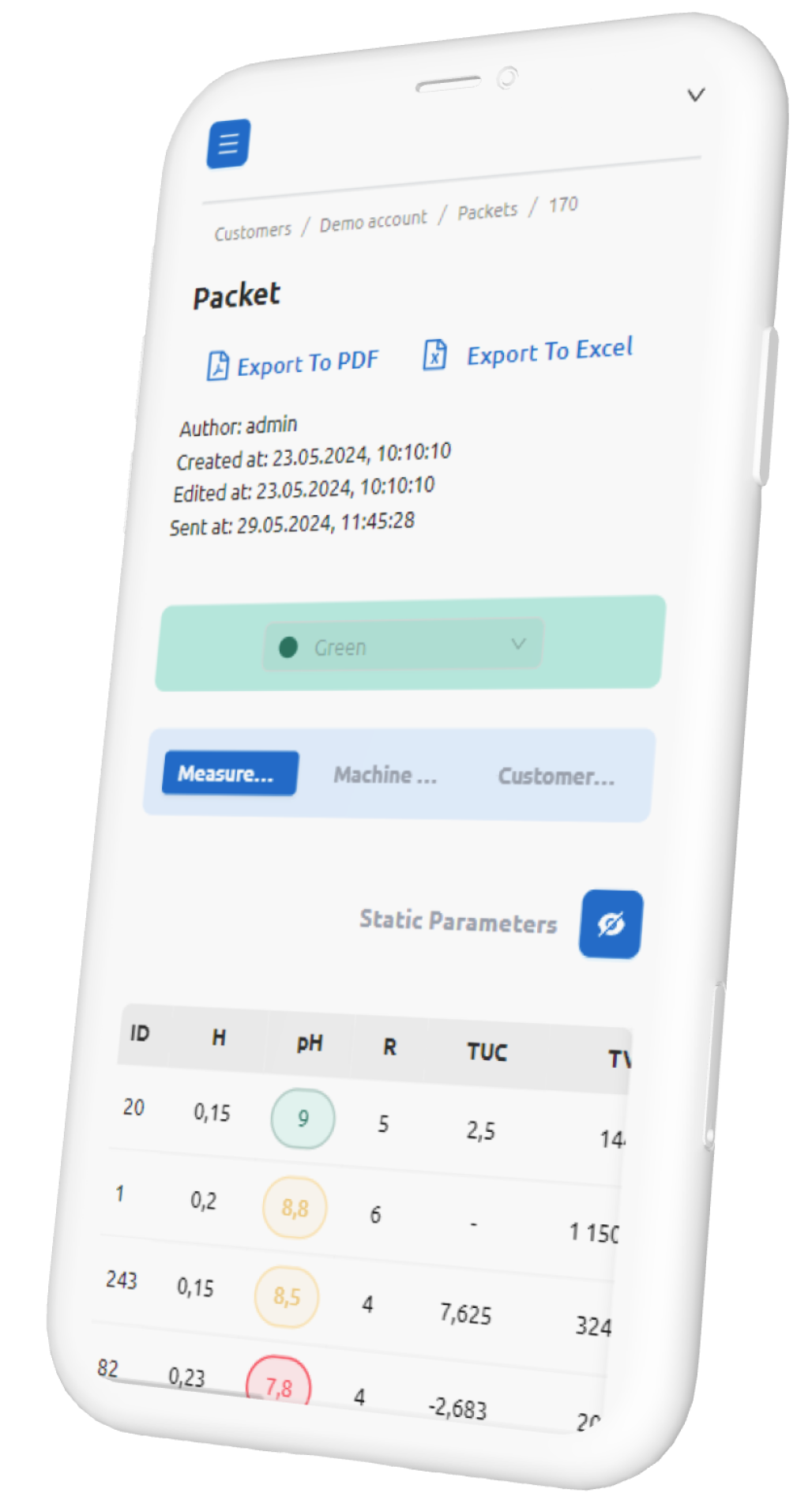

Reporting

- Generate various reports like “Report on Machine” or “Report on date”

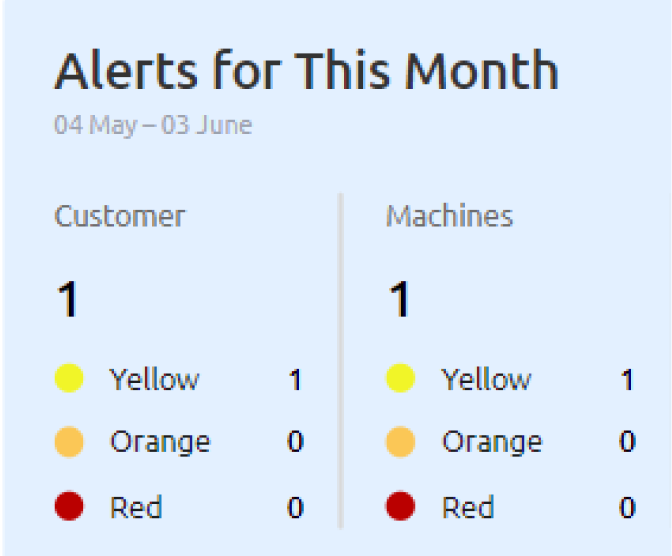

- Create alerts when something goes wrong and track them

- Add different attachments to alerts to explain what’s wrong

- Set up different alerts levels with corresponding notification to different managers

Calculations

- Calculate required top-up concentration per machine based on actual machine sump level

- Calculate corrections to the mixer (more on that below)

- Perform various calculations with parameters like Concentration =RefractometerReading * OpticalFactor or any other that you would like to create

Some special features that relate to metalworking fluids

We all know, that when you a lathe or milling machine works, there are two processes that occur at the same time: drag out of emulsion on chips and water evaporation.

If there was no water evaporation, then you would need to top-up machine with exactly target (or so-called “make-up”) concentration (for example, grinding is such a process, nearly 0 evaporation).

If there was no drag out on chips, then you would add just water, in other words, your top-up concentration would be equal to 0%. Depending on the type work you do your emulsion concentration will be every time different.

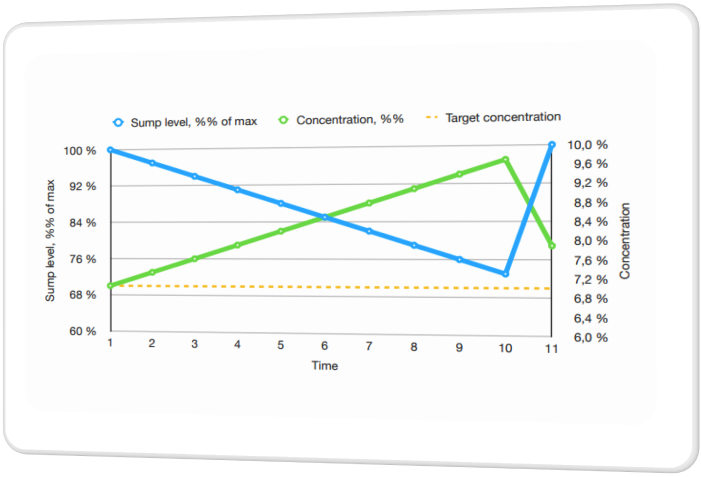

This is what happens if you have more of evaporation, than drag out on chips:

As you see, as machine sump level goes down, concentration rises pretty much in a sharp way and after filling in machine with 3% of top-up emulsion from mixer, you end up with 7,9% of concentration which is higher, than your target concentration of 7%.

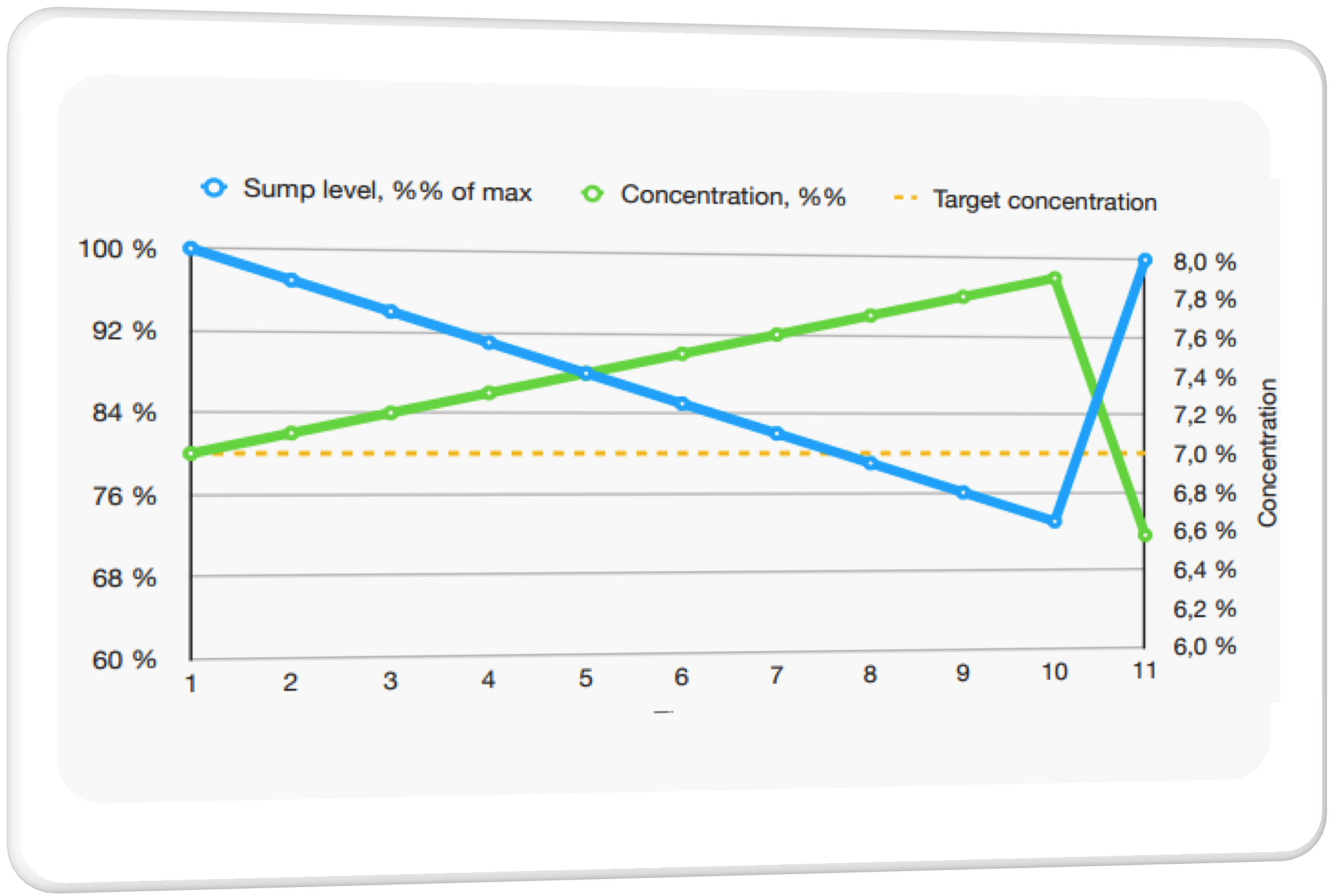

The opposite scenario - you have less heat but more chips produced in your work.

Here’s what to expect:

Let’s look into what it actually leads to, i.e.,“Show me the money”!

Imagine we have a setup like this:

230L

Tank volume

Machine tank volume is 230L

7%

Concentration

Target concentration 7%

3%

Topping-up concentration

Central mixer concentration is 3%

Scenario 1

After a few days you have a situation like this:

85%

Machine tank is full on

8%

Concentration

If you top up with 3% (default mixer concentration), you will end up with concentration of 7,25%. Not a big deal?

Indeed, but you could still add ca. 20L of water, saving some money on concentrate and get spot on 7% as a result. Here’s a very typical situation of one of our customers. Real field data, and believe it or not - this happens all the time everywhere.

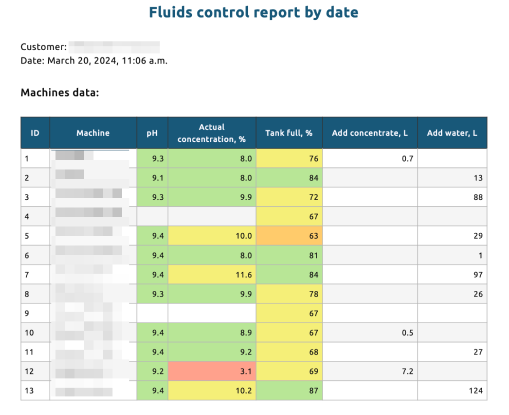

Here’s a very typical situation of one of our customers. Real field data, and believe it or not - this happens all the time everywhere:

In this example total amount of water that can be added to machines sumps is 406L for 13 machines. With topping-up concentration of 3% you save 12L of concentrate, or kinda €85. Given, that average consumption of a machine per day is ~20L, you may expect similar savings basically every week or so.

Scenario 2

What if your operator has not been topping up for a while and you get a situation like this:

50%

Machine tank is full on

9%

Concentration is

Then if you top-up from mixer, you will end up with concentration of 6% which is well below the target.

To compensate this deviation you need to add 2,3L of concentrate so that you will have exactly 7% afterwards. By doing this you decrease risks of bacteria growth, corrosion and short cutting tool life.

All these figures may be way more substantial if you take a machine with a sump of, say, 2 m3.And depending on operators responsibility level the risks related to deviations may also be very significant.What if your cutting fluid contains a lot of tramp oil?

In this case your refractometer shows you higher concentration, than it really is, and you are supposed to perform so-called titration in order to find the correct one and calculate the offset, using it every next time to adjust the refractometer reading.

This offset you apply to a machine in Easyfluid it will be used in all calculations down the road.

Sounds tedious, right?

It does. You really cannot do these calculations every time you are about to top-up machine sump, can you?

Lucky enough, EasyFluid comes to the rescue!

It calculates everything - all you need is to enter refractometer readings and fluid level in the machine sump! As a result:

Create your free account for 1 machine!

Do I have to use these calculations?

No, you may opt in for just logging the data and monitoring your key indicators, setting aside deviation corrections calculations.

Well, sounds good. How to start?

We provide our customers with assisted setup, that means, we add your machines and your cutting fluid. We setup your users, their rights, and you are good to go! We will walk-through all the steps, show how it works and answer all your questions.

Wanna try it yourself? Create your free account for 1 machine!

Create AccountHow about a demo?

Sure! We will walk-through all the steps, show how it works and answer all your questions..

Pricing

Rate per machine added per month

€4.90

incl.EasyFluid remote monitoring.

Flat rate per company

€19.90

per month per company.

or enjoy 10% off discount for annual subscription.

*One machine is free forever, enter your data in our demo calculator and we`ll create your free accound